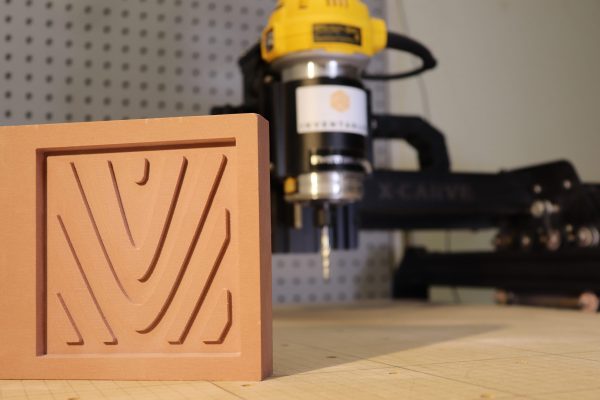

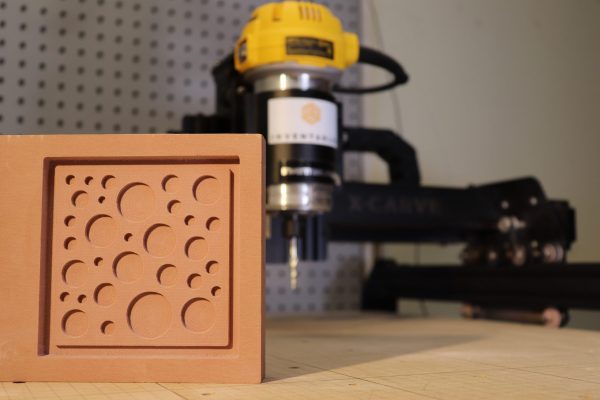

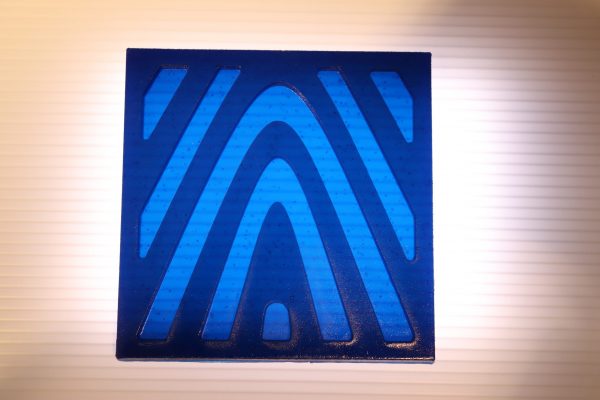

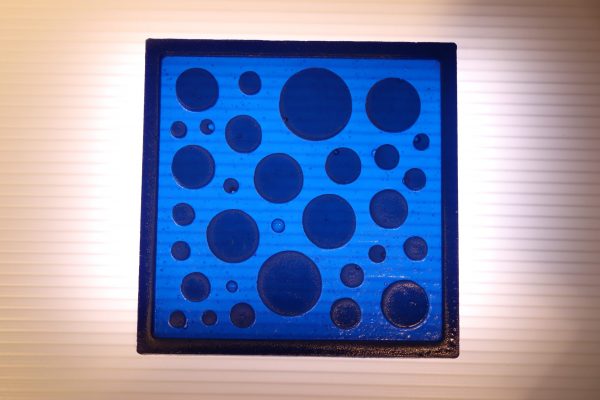

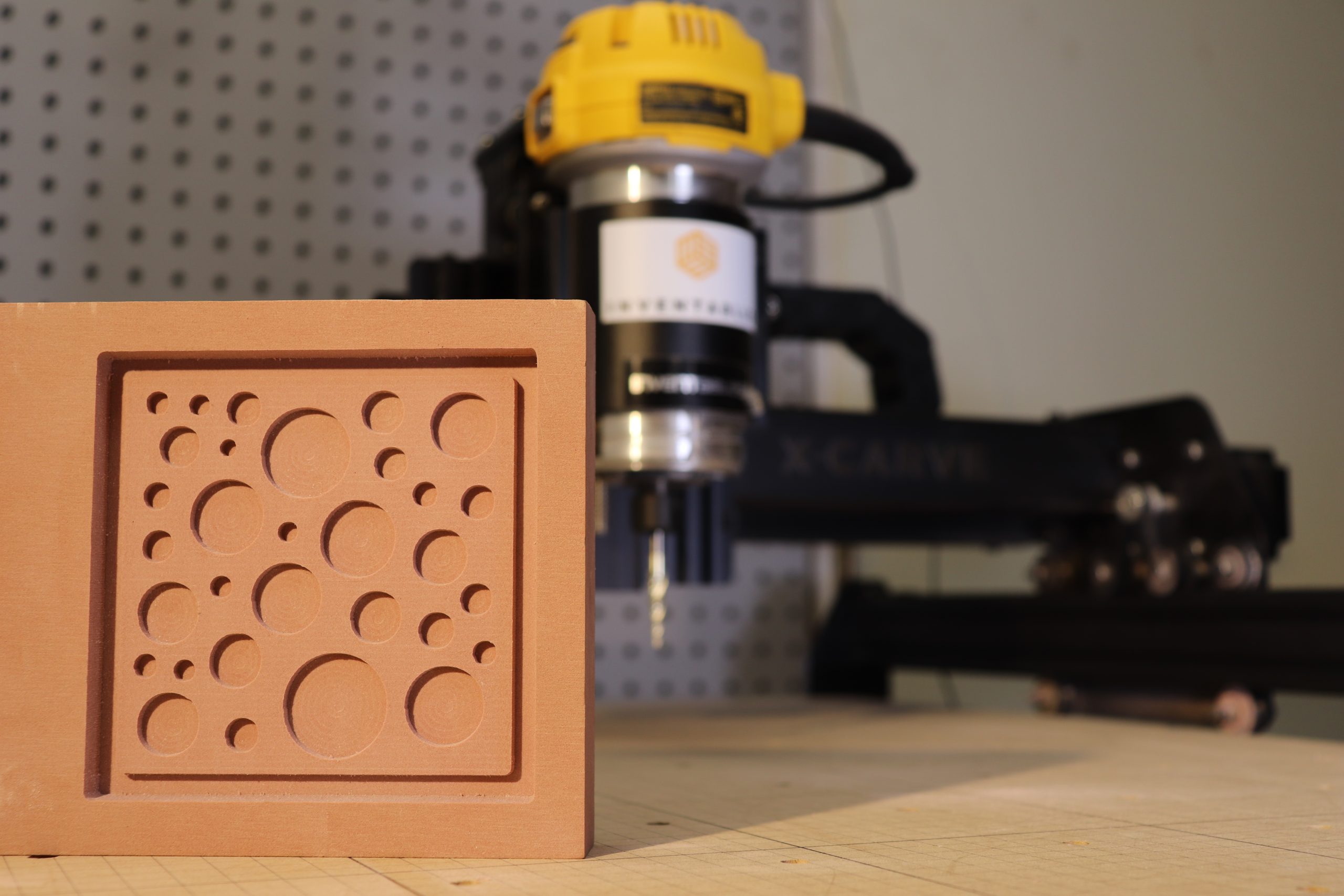

I recently did some urethane casting to recreate some small bumpers that were no longer commercially available. The process was new and interesting so I thought that I’d make some custom drink coaster molds using the X-Carve CNC from inventables. For the first time, I used a tapered endmill. The taper of the endmill naturally creates a relief angle to the mold, making coaster removal easier once the urethane has cured. I made several different designs. The Fusion 360 design file links are below as well as links to other items used in the project. Thanks to Inventables for sponsoring my creative adventures!

Affiliate links to the items used in this project: (Thanks for your support!)

X-Carve CNC Machine – https://bit.ly/2xvzHwk

Easel Design Software – https://bit.ly/2Vf0FBH

Vacuum pump – https://amzn.to/3jeNPg9

Vacuum chamber – https://amzn.to/338Lmym

Silpak Urethane – I used RU-385 – http://bit.ly/silpak

Tapered Endmill – http://bit.ly/taperedendmill

Designs created using Fusion360 CAD/CAM software http://aklam.io/hiHjFf

Bubble coaster mold – https://a360.co/3i5TVy8

Curve coaster mold – https://a360.co/339o0bG

Help support the channel: – PayPal https://www.paypal.me/neo7cnc