Inventables ask if I could come up with a shop organization project that could utilize the X-Carve CNC. It’t didn’t take me long to think of several ideas but this one had an immediate need.

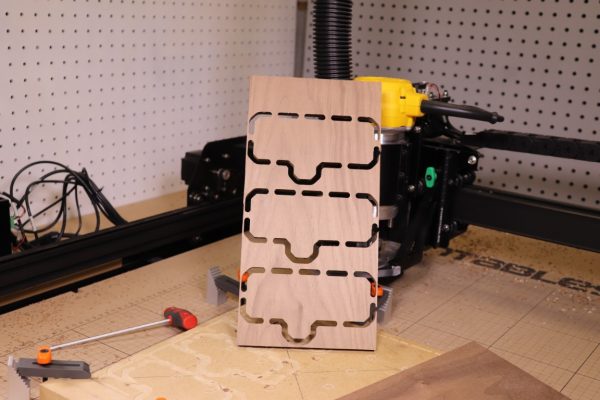

When I found this style of wrench, I bought only the individual sizes that I used most. I had 3 different sizes in Imperial and Metric. Not even remotely close to a full set. I recently splurged and bought more wrenches to better fill out the collection but this posed a new issue. Where to keep them? I use them often and there’s no room in my tool boxes so they usually sit under or around my CNCs or in a wooden pen cup on the bench. With more wrenches, the cup is not an option as it too easily tips. Also, tossing them under the CNC makes them a pain to retrieve. The easy and obvious solution is to just get one of the typical stands, but that takes up valuable bench space. Just hang it on the wall then, right. The racks I’ve seen stick out to far and you cant easily see the sizes on the wrenches. So I came with my own solution. These holders address all the previously mentioned issues. There modular and can nest together in many orientations. They magnetically hold the wrenches securely while showing the size. They can be flat mounted to the wall, ceiling, CNC machine, bench, basically anywhere. This is great because I have some duplicate wrench sizes that I keep at each machine. Oh…. and they look pretty neat and are made out of Black Walnut.

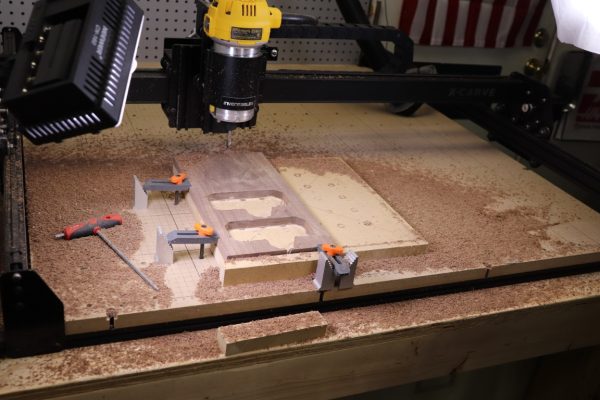

I used the CAD program, fusion 360, to quickly create the design knowing that the board I would be using was 1/2 inch thick (12.5mm). The first iteration of the design had 0.0625 (1/16) fillets in the corners that would force me to use a 1/8 endmill. When I moved on to designing the CAM strategy, I quickly realized that with the amount of material I needed to remove, it would take forever with a 1/8 endmill. I changed the fillets to 0.125 (1/8) so I could use a 1/4 inch endmill and that worked great. There was no need for thicker material and the recess cut only needed to be deep enough to prevent side to side movement. I also like the look of the wrench being proud of the holder. I primarily used Black Walnut but did experiment with layering a 1/8 piece of maple on to Black Walnut for some contrast. I think it looks great but I needed a longer 1/4 endmill than what I had on hand due to the added thickness before I’ll make more. The YouTube video and products links are below as well as a photo gallery. I really like the way they turned out.

X-Carve CNC machine from Inventables

Easel Design Software – Setup a FREE account to check it out

CAD Design Files

Fusion 360 file for small holder

Fusion 360 file for medium holder

** A #4 x 3/8 brass Phillips screw was used to hold most of the magnets in.