SainSmart contacted me to see if I was interested in reviewing and providing feedback on their upcoming Genmitsu Jinsoku LC-40 desktop laser engraver. When they mentioned that it used linear bearings for the sliding elements. This spoke to my DIY CNC background and I was curious to see how well this upper-end part was incorporated into the LC-40. I used similar linear bearings to build one of my first CNC machines.

Packaging

The unit arrived extremely well packed in an unbranded, sturdy cardboard box with ample foam packaging. There was no damage and nothing was missing.

Assembly

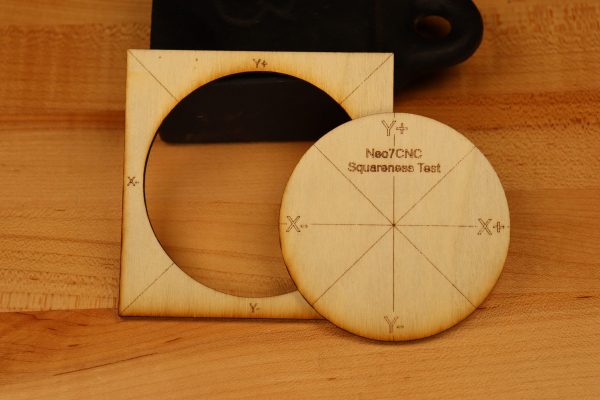

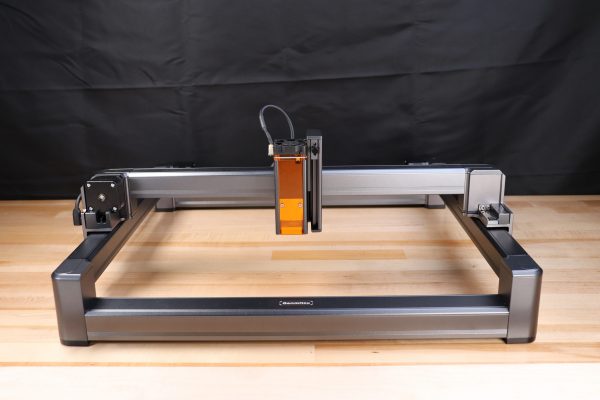

Assembly was very easy, due to all the motion components being fully assembled. You just connect the 4 corners, attach the X axis, and mount the laser head. All the needed tools were included. The manual had all the instructions I needed to assemble the unit without me having to look it up on the Internet which was nice. It took me about 20 minutes to assemble. I did manage to pinch a wire on the joint that connects the left side of the X axis to the left Y axis. I discovered this issue when I performed the Neo7CNC squareness test. The test reveled that the LC-40 was not square. In troubleshooting the issue I discovered the pinched wire. I corrected the issue and re-ran the squareness test. The LC-40 passed with flying colors this time being only the second machine to do so that I’ve tested!

Features of the Genmitsu Jinsoku LC-40

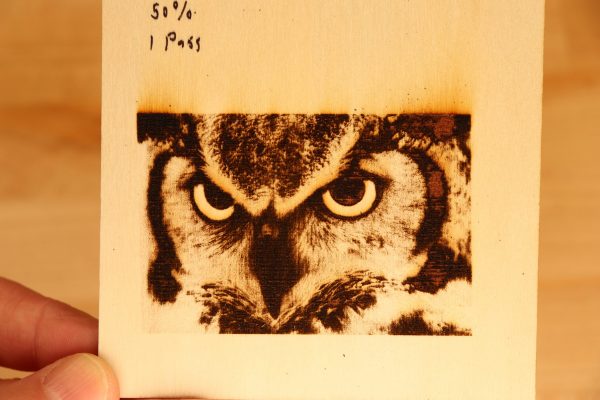

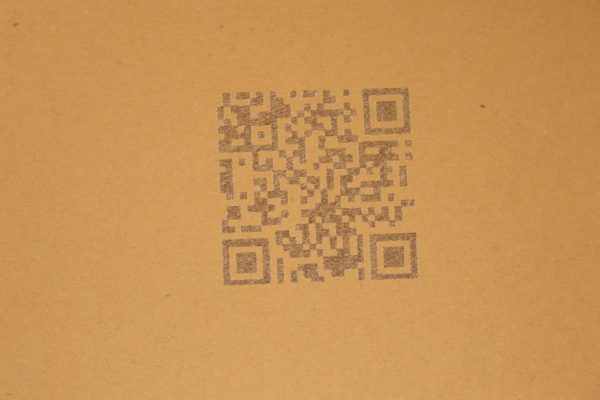

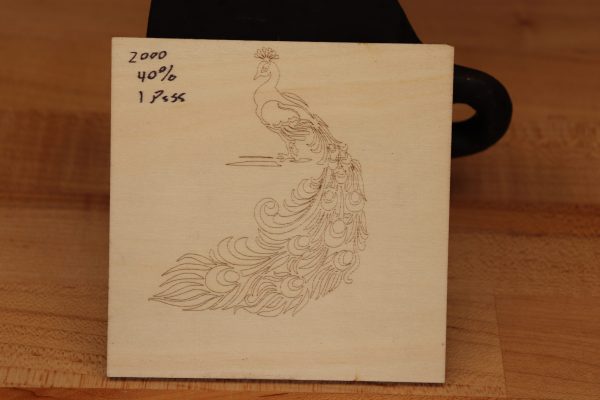

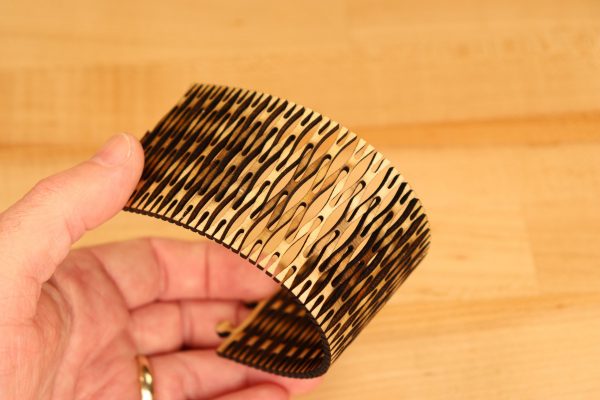

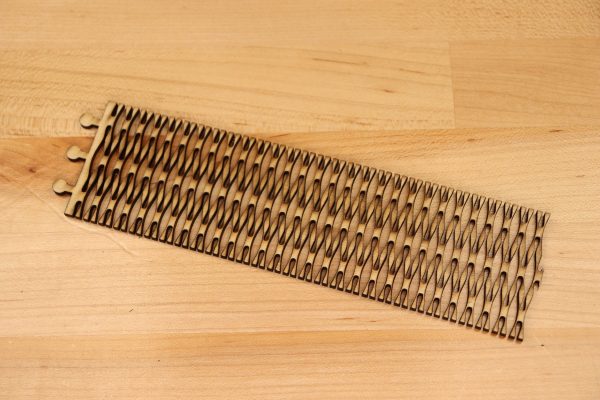

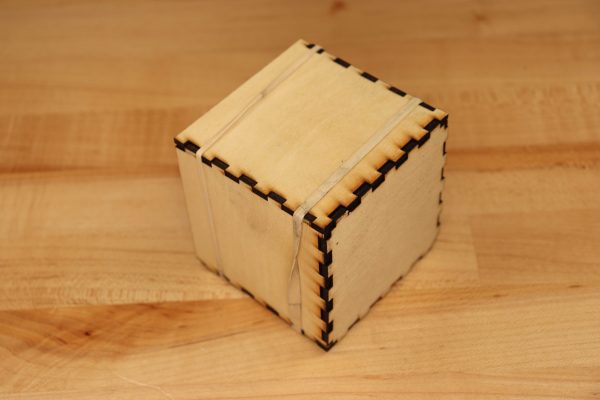

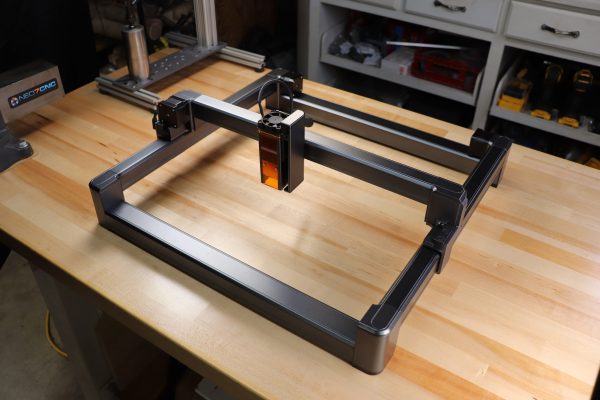

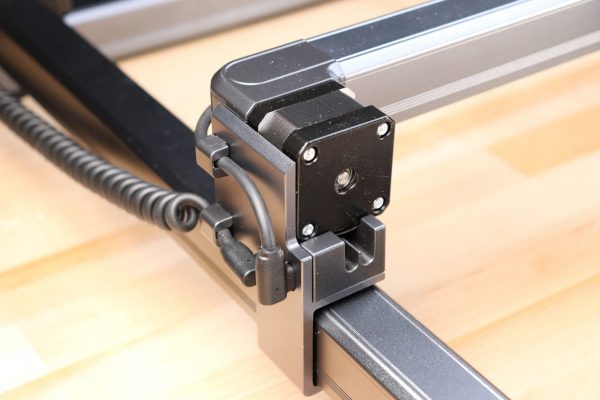

The Genmitsu Jinsoku LC-40 has a good complement of features. Some of the most visible features are the unique construction of the machine. The Jinsoku LC-40 uses a unique aluminum extrusion for the structure which is different from most machines in the price range. Most machines utilize a T-slot type profile. that allows those machines to use roller wheels for the motion components. The Jinsoku LC-40 breaks away from this standard design as well. It utilizes linear bearings for the motion components. Linear bearings are more readily found in high-end consumer 3D printers, CNC machines, production automation and robots. This feature was what intrigued me the most and made me want to review the LC-40. The LC-40 has a working area of 400x400mm which is pretty standard. It also uses a 5.5w laser head just like the one on the Atomstack A5 and Longer Ray5. The laser focus with the LC-40 is very easy. The focus block is stored in a convenient holder on the right side of the X axis (left and right movement axis). The laser height adjustment is also easy and can be done with one hand. The height adjustment screw is forward facing and there is a ruler etched inside the slider that the head rides in. Another nice feature is the wire management. The LC-40 uses USB-C type wires to connect to the motor and a similar cable to connect to the laser head. This makes installing them a breeze. There are also special wire retainers that clean up the wiring even further. Be sure to look at the photo gallery down below to see just how clean it is. This machine has 2 different software (firmwares) that it can run. The standard firmware lets you use the basic software as well as use your mobile device to run the LC-40 over Bluetooth 5.0. The mobile app lets you easily engrave images, doodles, text, bar codes, QR codes and more. I easily started the app for the first time and was able to engrave a custom QR code on some Kraft paper. The only issue I encountered was that the app didn’t let me preview where the engraving was going to take place in the working area of the LC-40. The preview ability makes it easy to set the focus on the material you’re using. I was able to pause the engraving shortly after starting it and that allowed me to set the focus. As a programmer, this is a fairly easy software fix and hopefully we’ll see this feature in a future update. I run my machines with LightBurn so this is only an issue for me while I’m testing the LC-40. The second firmware version allows you to use the Lightburn software for control (my go-to software). The controller is minimal but adequate, having a power and USB A and B connectors as well as a power and repeat job/utility button. It should be noted that the interfaces and buttons are on the rear of the machine, not the side or front like most machines I’ve tested.

Updates to the final version

SainSmart sent me a change log of issues that I’m told will be addressed in the newer version that is available for pre-order now.

Issue 1. The Z height adjustment knob is to small – They are increasing the diameter from about 6mm to 12mm.

Issue 2. The spiral cable connecting the X-axis and Y-axis is not long enough for proper movement. – Changed to long cable. (I experienced this issue)

Issue 3. The cable clips are too stiff to be easily installed. – Clip material made more flexible so it’s easier to install.

Issue 4. Used can easily install the X-axis out of square. – Positioning pins will be added to aid in proper assembly. (I experienced this issue because of the pinched wire)

Issue 5. The screws connecting the machine frame are too short and can easily get stripped. – Changed from M3 to M5 screws.

Issue 6. The laser module connection screws can become loose during shipping causing it to tilt. – Spring washers added to avoid this.

Issue 7. The front and rear modules (beams) are different lengths causing the machine to be out-of-square. – Stricter quality inspection to increase precision.

Safety

The manual also covers the very important aspects of safety and they can’t be repeated enough. Though small, this is a laser that can cause serious damage. Read and follow all the safety warnings. As a basic rule, don’t look at the laser light at all, make sure what you’re cutting won’t give off toxic fumes (like PVC, ABS, Epoxies, etc.), Use only in an extremely well ventilated space and don’t stare at the beam. Safety is your responsibility.

Fume Extraction

I setup a basic fume extraction system with an 6″ inline fan, some 6″ ducting and a 6″ blast gate. I created a simple enclosure with some 24×36 inch sheets of corrugated plastic. I was pleased with how well it works. The fan pulls from the enclosure and vents to the outside. the blast gate is used to allow fresh air in from the outside (well away from the exhaust) so that the fan has the ability to pull freely. Links to what I used for this are down below.

Software

I used Lightburn ($40 version) for all these test jobs. It’s feature rich compared to LaserGRBL but both will work. I like Lightburn because I can create just about much anything inside it. It’s great for cutting or on the fly creation as it allows you to draw, type, scale, etc right in the program.

Summary

The Genmitsu Jinsoku LC-40 from SainSmart is build like a “brick house” as we say in the south (this is a good thing). It’s very sturdy and well built using structure and components that I haven’t seen in this LED based desktop laser space before. It’s one of the most “finished” looking machines I’ve tested with it’s clean lines, unique frame and tidy wire management. I’d love to see a 10w or greater version but the 5.5w version that I tested did as well as any other machine in that power range that I’ve tested. It’s a great machine for the price! Be sure to view the pictures below and watch the YouTube video if you haven’t already. As always links are below.

*** NOTE ***

The version of the LC-40 I tested is not the same machine that’s being offered in the pre-sale going on now. It should be improved based on the update sheet that SainSmart shared with me but I have not seen or tested the final production product.

Genmitsu Jinsoku LC-40 main website pre-order page https://shrsl.com/3hzg8

Member Program can get extra $30 coupon. Look for the FREE sign up link on the page from the link above.

HAYEAR 26MP HDMI Digital Microscope https://bit.ly/3G20Owk

Software:

LaserGRBL Software (free) https://lasergrbl.com/download/

LightBurn Software (free trial/$40 to buy) https://lightburnsoftware.com/

Download the Neo7CNC Squareness Test LightBurn File HERE

Addition items used in the video:

Stainless steel tumbler – https://amzn.to/3gwJoO4

Stainless steel military style dog tags (qty 100) – https://amzn.to/3B7fVDY

Slate drink coaster set – https://amzn.to/3GQr3GF

Kydex 8×8 Sheet (x2) – https://amzn.to/35SAMzC

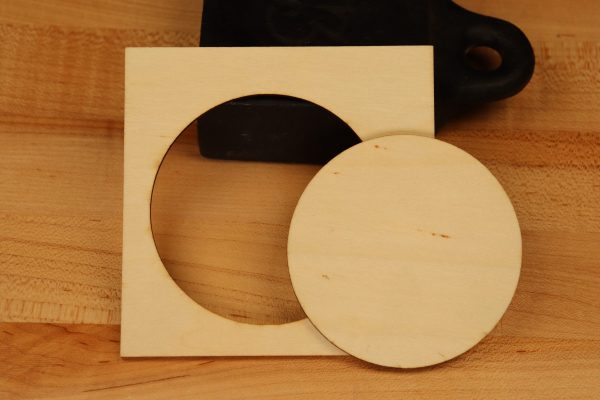

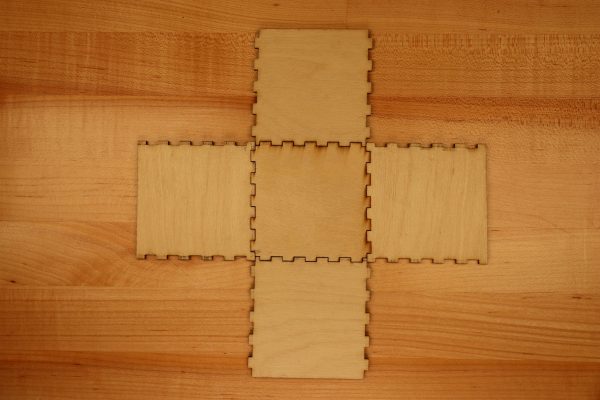

Wood squares – https://amzn.to/33RUNBW

Wood 3 inch circles – https://amzn.to/3Ic1vnM

Kraft paper tags – https://amzn.to/3foiLK9

Painted aluminum business card blanks – https://amzn.to/3yj6q2E

Stainless steel business card blanks – https://amzn.to/3bAn0RL

Anodized aluminum blank dog tags – 10 pack – https://amzn.to/33h8HAg

To create you own fume extraction system

6″ inline blower – https://amzn.to/3ftxCmu

6″ duct kit – https://amzn.to/3eWjVh0

6″ flange – https://amzn.to/33UlbuG

6″ blast gate – https://amzn.to/3hyPNKs

Like my “Not A Drill” T-shirt? Find it and many more here – https://bit.ly/3HHEb25

Support the channel: – PayPal https://www.paypal.me/neo7cnc