LED Can Light – Start to Finish

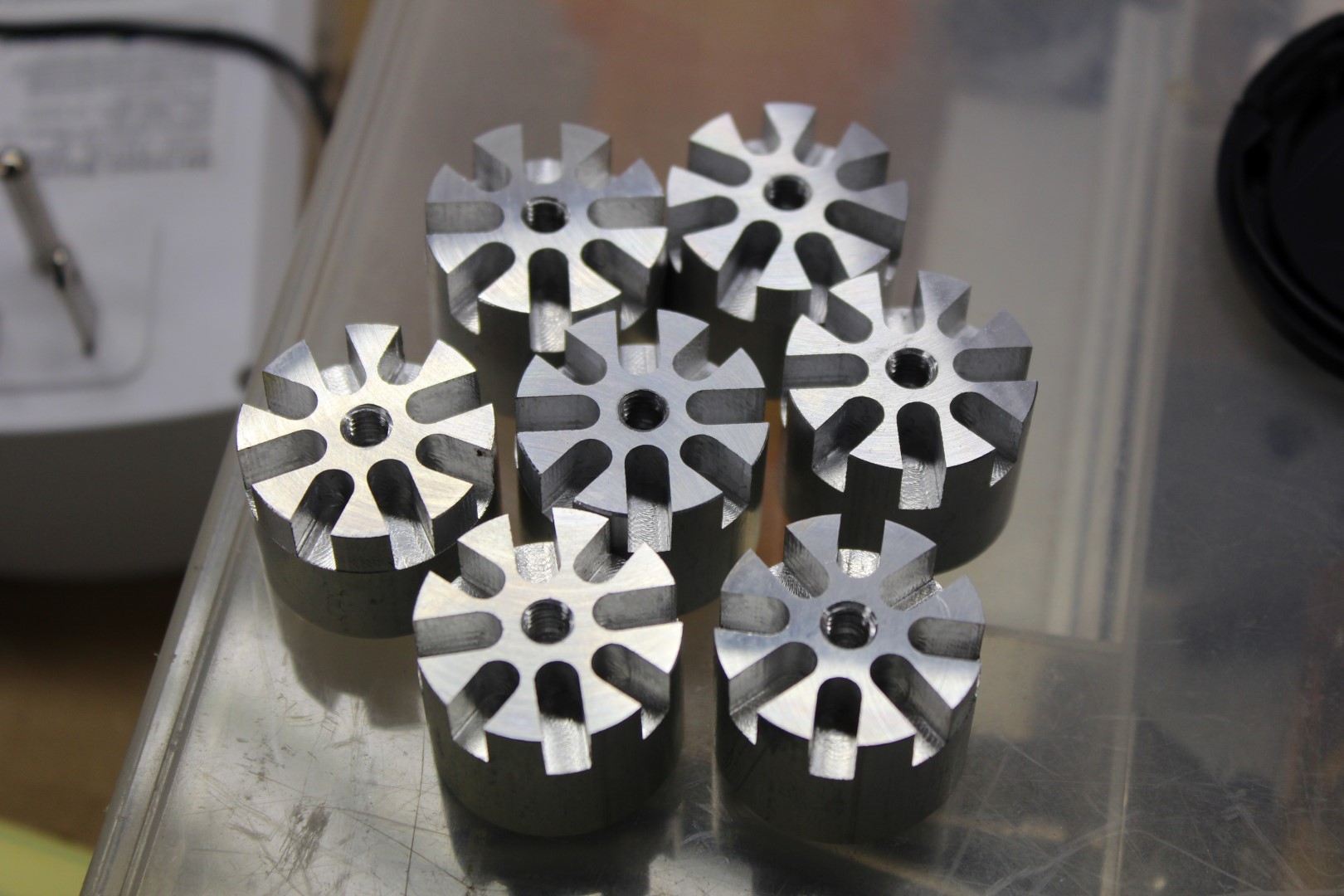

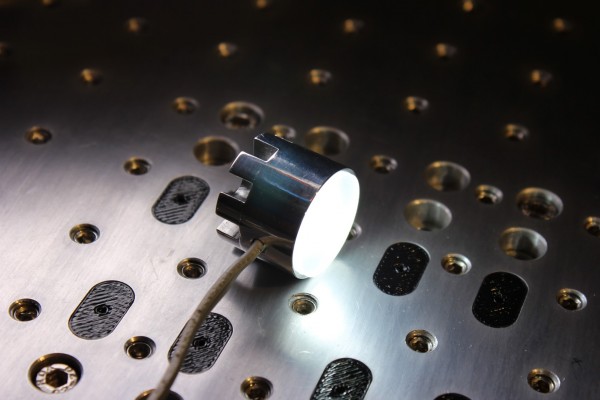

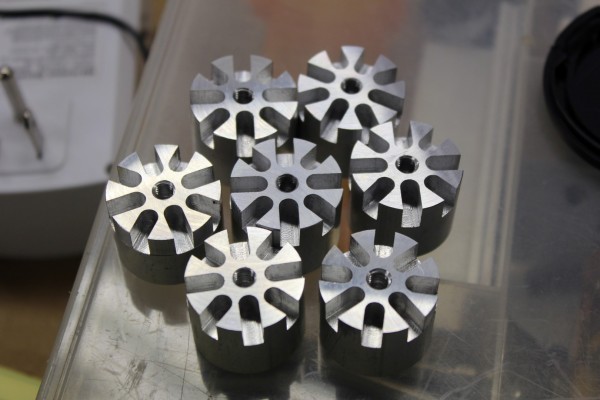

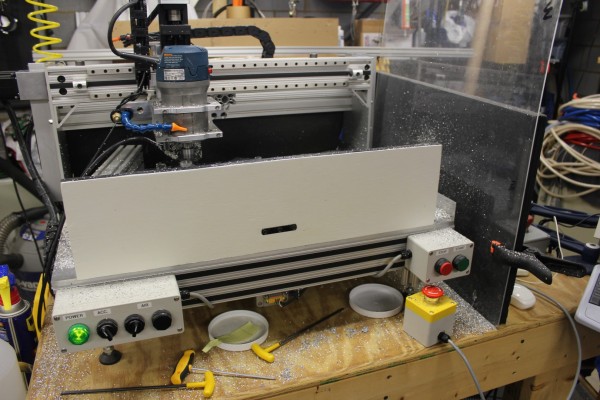

In this start to finish project we go through the entire process from Ideal to finished part. First we do the 3d design on the computer using Onshape. We then CAM (create the tool paths that tell the CNC machine how to actually cut the part) using BobCAD/CAM. Next we use a 5C collet fixture to hold the stock and test cut the part in plastic. Finally we cut the design from 1 inch (25mm) 6061-T6 aluminum bar stock. The lens is made from 1/8 frosted acrylic. You can tell in the pictures that this process made a big mess! The tolerances on the lens were “spot on”. The KR33 CNC is a beast of a little machine

I polished the aluminum version and that made it pop. It’s a nice, compact unit. I still need to finish them and mount them to the machines. One issue I have is finding good wire to use.

One Comment